In the cleanroom system, Cleanroom Pass Thru is a small enclosed

device installed between clean rooms and between clean rooms and

non-clean areas for transferring items. The Pass

Box is an indispensable auxiliary equipment that can reduce the

frequency of personnel entering and exiting the clean area and

reduce the risk of cross contamination.

Product Features

1. Stainless steel material

The whole machine is made of high-quality 304 stainless steel, and

the surface is frosted or mirror polished. It is

corrosion-resistant and rust-proof, easy to wipe daily, and

suitable for long-term use in areas with strict cleanliness and

hygiene requirements.

2. UV ultraviolet sterilization configuration

The built-in high-efficiency UV ultraviolet lamp can quickly

disinfect and sterilize the inside of the Pass

Through Box, reduce the risk of microbial residue, and ensure the sterile

environment during the item transfer process. It is especially

suitable for pharmaceutical workshops and Active Pass Box dust-free

operation areas.

3. Interlocking door design to prevent cross contamination

The doors on both sides use a mechanical or electronic interlocking

system to ensure that when one door is opened, the other door is in

a locked state, avoiding direct convection of air inside and

outside the clean room, and improving the overall safety of the

clean room system.

4. Diverse customization options

Amber provides a variety of specifications, sizes and functional

configurations, supports OEM/ODM customization, meets the needs of

different Cleanroom Pass Thru application scenarios, and can be

equipped with HEPA high-efficiency filtration, differential

pressure display, wind speed adjustment, intercom function and

other extended functions.

Active Pass Box application scenarios

1. Pharmaceutical industry

In the raw materials, intermediate products, finished product

packaging and other links of the pharmaceutical workshop, Active

Pass Box can effectively separate different clean level areas to

avoid the risk of contamination caused by frequent personnel

movement.

2. Laboratories and testing centers

Various high-level Pass Box Laboratory environments, such as cell

laboratories, microbial testing centers, biosafety laboratories,

etc., often use UV ultraviolet clean transfer windows to ensure the

safety of experimental samples and the environment.

3. Electronic semiconductor industry

In the production of semiconductors, optoelectronics and precision

electronic products, Cleanroom Pass Box can ensure the safe

transfer of materials in different clean level areas to prevent

static electricity and dust pollution.

The difference between SUS201 and SUS304

| Item | SUS201 | SUS304 |

| Material composition | High in manganese and low in nickel | High nickel content, stronger corrosion resistance |

| Rust resistance | Medium, suitable for general clean room use | Better, suitable for pharmaceutical/laboratory environment |

| Price | Low price, high cost performance | Slightly higher, suitable for high-demand places |

Specifications

| Model | CDC-C-400 | CDC-C-500 | CDC-C-600 | CDC-C-800 |

| Out size(W*D*H) | 600*470*1000 | 700*570*1100 | 800*670*1200 | 1000*870*1400 |

| Inner size(W*D*H) | 400*400*400 | 500*500*500 | 600*600*600 | 800*800*800 |

| Filter size mm | 260*260*90 | 330*280*90 | 430*380*90 | 630*580*-90 |

| Motor Power | 200W | 300W | 400W | 600W |

| Air Speed(m/s) | 0.45±20% |

| Cleanliness | Grade A |

| Noise | <65dB |

| Showing Time | 0-99 min adjustable |

| Voltage | AC 220V/50HZ |

FAQ

Q1: What is the difference between Active Pass Box and ordinary Pass

Box?

A: Active Pass Box is equipped with HEPA high-efficiency filtration

system and fan unit, which can dynamically purify the internal air

when the items are delivered, maintain the cleanliness of the

internal space, and effectively isolate different clean level

areas. Ordinary pass boxes only have basic item delivery functions

and are not equipped with air purification systems.

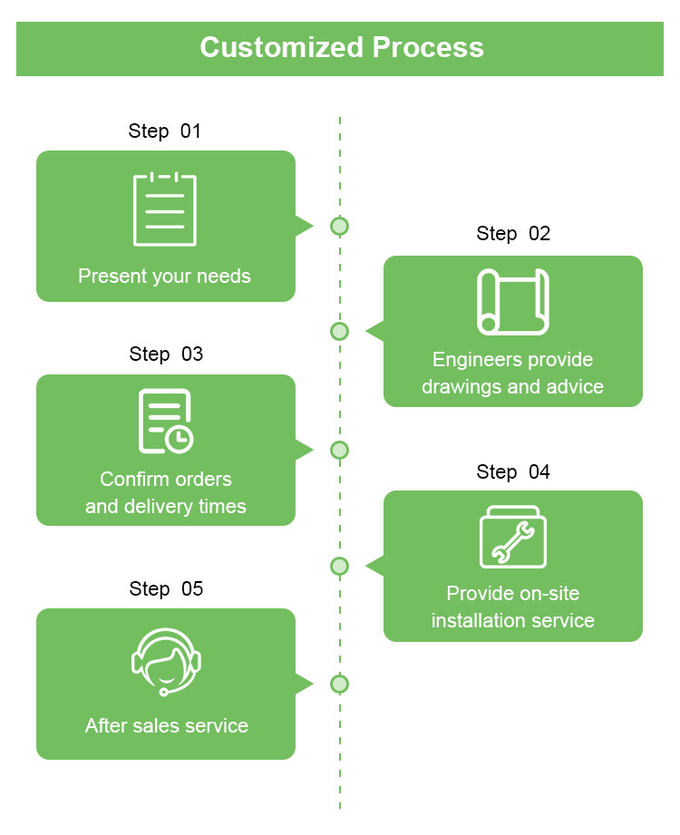

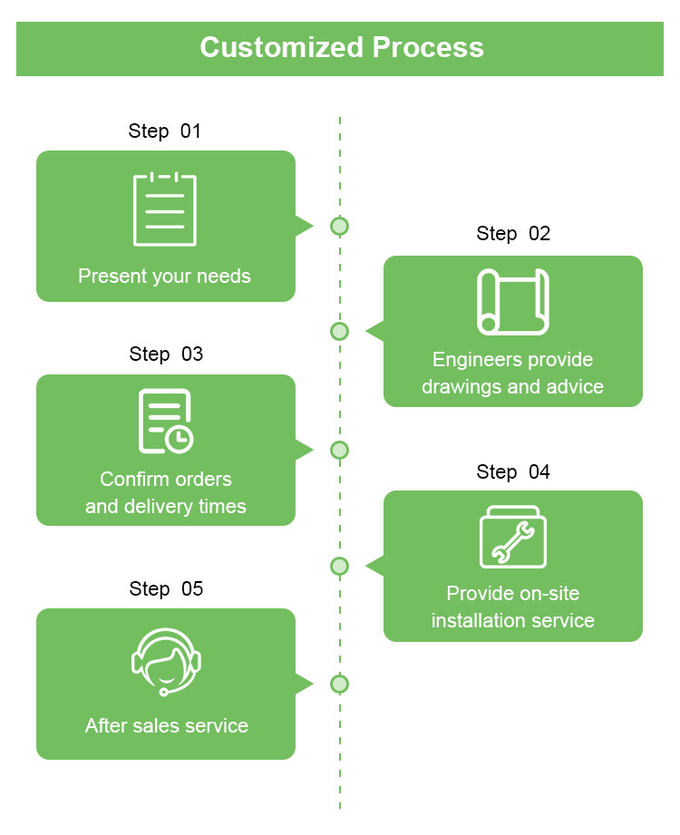

Q2: Can the size and function of the pass box be customized?

A: Yes. Amber provides standard models with multiple specifications

and supports OEM/ODM customization. It can customize the size,

material, UV lamp, HEPA filter, electronic intercom, differential

pressure gauge and other functional configurations according to the

different cleanroom layout requirements of customers to meet

various Cleanroom Pass Thru usage scenarios.